2200W ECM Motors Permanent Magnet Motor 220V/380V/460V Integrated with Driver

Product Details

Introduction to the 2200W ECM Motor for Fan Applications

The 2200W Electronically Commutated Motor (ECM) represents the cutting edge of high-performance motor technology for industrial air movement systems. Designed for extreme-duty applications requiring massive airflow and pressure capabilities, this powerful motor combines intelligent control, exceptional reliability, and unprecedented energy efficiency, establishing new standards for large-scale ventilation systems where operational excellence and energy conservation are critical.

Core Technology: Advanced ECM Architecture

An ECM is a sophisticated brushless DC motor featuring an integrated microprocessor that enables precise electronic commutation and dynamic speed control. This represents a quantum leap from conventional AC induction motors by functioning as an intelligent, demand-based system. The motor continuously self-adjusts its rotational speed and torque output to match exact real-time ventilation requirements, eliminating the substantial energy waste associated with fixed-speed motors operating against system resistance.

Key Features and Benefits

1. Exceptional Energy Efficiency and Operational Economy:

Premium Efficiency Performance: Maintains outstanding efficiency levels (typically 87-94%) across entire operating range

Substantial Energy Conservation: Achieves 65-75% energy savings compared to conventional motors

Optimized Operational Costs: Dramatically reduces electricity consumption while delivering exceptional ROI

Environmental Leadership: Supports zero-carbon initiatives and exceeds modern environmental standards

2. Advanced Intelligence and Precision Control:

Smart Demand-Based Operation: Advanced microprocessor enables exact speed matching to system requirements

Constant Airflow/Pressure Maintenance: Automatically compensates for system changes like filter loading or damper adjustments

Soft Start/Stop Capability: Eliminates high inrush current (typically <1.5x running current)

Building Management Integration: Native compatibility with BMS through multiple protocol support

3. Superior Reliability and Performance:

Industrial-Grade Construction: Engineered for continuous operation in extreme environments

Advanced Thermal Management: Built-in temperature monitoring and smart overload protection

Acoustic Optimization: Significant noise reduction through precision speed control

Maintenance-Free Design: Brushless architecture with premium sealed bearings ensures extended service life

Technical Specifications

Rated Power: 2200 Watts (3 HP equivalent)

Motor Technology: Advanced brushless DC with neodymium permanent magnets

Control System: Integrated microprocessor-based variable frequency drive

Input Voltage: 380-480V AC, 50/60Hz (Three Phase)

Control Interfaces:

0-10V DC analog control

4-20mA current loop

PWM signal

Modbus TCP/BACnet IP protocols

CANopen connectivity

Efficiency Class: IE5 super premium efficiency

Protection Rating: IP56 (dust protected and powerful water jet resistant)

Thermal Class: F (155°C) insulation system

Rated Power: 2200 Watts (3 HP equivalent)

Motor Technology: Advanced brushless DC with neodymium permanent magnets

Control System: Integrated microprocessor-based variable frequency drive

Input Voltage: 380-480V AC, 50/60Hz (Three Phase)

Control Interfaces:

0-10V DC analog control

4-20mA current loop

PWM signal

Modbus TCP/BACnet IP protocols

CANopen connectivity

Efficiency Class: IE5 super premium efficiency

Protection Rating: IP56 (dust protected and powerful water jet resistant)

Thermal Class: F (155°C) insulation system

Application Scope

This high-capacity motor is engineered for demanding industrial applications:

Large Industrial Ventilation Systems

High-Capacity Air Handling Units (AHUs)

Industrial Process Cooling Fans

Data Center Cooling Systems

Large Warehouse Ventilation

Manufacturing Facility Air Management

Smoke Extraction Systems

Large Commercial Building Pressurization

Tunnel Ventilation Systems

Industrial Drying Applications

Performance Advantages:

Energy Savings: Up to 75% reduction in energy consumption

Precision Control: ±1% speed regulation accuracy

Reliability: >100,000 hours design life

Acoustic Performance: <75 dB(A) at 1 meter

Power Factor: >0.98 across entire operating range

Summary: The 2200W ECM motor represents the pinnacle of intelligent motor technology for industrial ventilation applications. It delivers unprecedented energy savings, precise environmental control, and exceptional reliability while significantly reducing total cost of ownership. Its advanced connectivity features and premium efficiency make it ideal for modern smart industrial applications, providing both immediate energy savings and long-term operational benefits that justify the investment in state-of-the-art motor technology. The motor's ability to maintain peak efficiency across its entire operating range makes it particularly suitable for applications with variable load requirements, ensuring optimal performance in any operating condition.

| Power kw |

Voltage V |

Frequency Hz |

RPM range |

Install Position |

Weight kg |

Efficiency % |

Power factor |

Current | Working Temp |

Torque N.m |

Energy Efficiency |

Protect Grade |

Insulation Class |

Motor Price (USD $) |

Driver Price (USD $) |

| 2.2 | 220 | 50/60 | 500-3000 | Verical/ Horizontal |

18.9 | 88.1 | 0.91 | 12.47 | -15~+40℃ | 42.1-7.1 | IE4 | IP66 | F | 305 | 67 |

| 2.2 | 380 | 50/60 | 500-3000 | Verical/ Horizontal |

18.9 | 88.1 | 0.91 | 4.17 | -15~+40℃ | 42.1-7.1 | IE4 | IP66 | F | 305 | 67 |

| 2.2 | 460 | 50/60 | 500-3000 | Verical/ Horizontal |

18.9 | 88.1 | 0.91 | 3.44 | -15~+40℃ | 42.1-7.1 | IE4 | IP66 | F | 305 | 67 |

| MODEL | Power Voltage | AC motor Labeled power |

AC motor Actual power consume |

EC motor Actual power consume | Power saving per hour (kWh) | Power saving 12 hours per day (kWh) | Monthly power saving (kWh) |

Annual power saving (kWh) | Save USD every year (Note: 0.12$/kWh) |

| GFPM0.37KW-1450RPM | 220V | 370W | 526W | 350W | 176W | 2.11 | 63 | 770.00 | 92.4 |

| GFPM0.55KW-800RPM | 380V | 550W | 800W | 406W | 394W | 4.73 | 142 | 1726.00 | 207.12 |

| GFPM0.55KW-800RPM | 220V | 550W | 900W | 400W | 500W | 6 | 180 | 2190.00 | 262.8 |

| GFPM0.75KW-1000RPM | 380V | 750W | 1130W | 730W | 400W | 4.8 | 144 | 1752.00 | 210.24 |

| GFPM0.75KW-1500RPM | 220V | 750W | 1250W | 850W | 400W | 4.8 | 144 | 1752.00 | 210.24 |

| GPFM1.1KW-650RPM | 380V | 1100W | 1670W | 1160W | 510W | 6.12 | 184 | 2234.00 | 268.08 |

| GFPM-1.1KW-650RPM | 220V | 1100W | 2200W | 1200W | 1000W | 12 | 360 | 4380.00 | 525.6 |

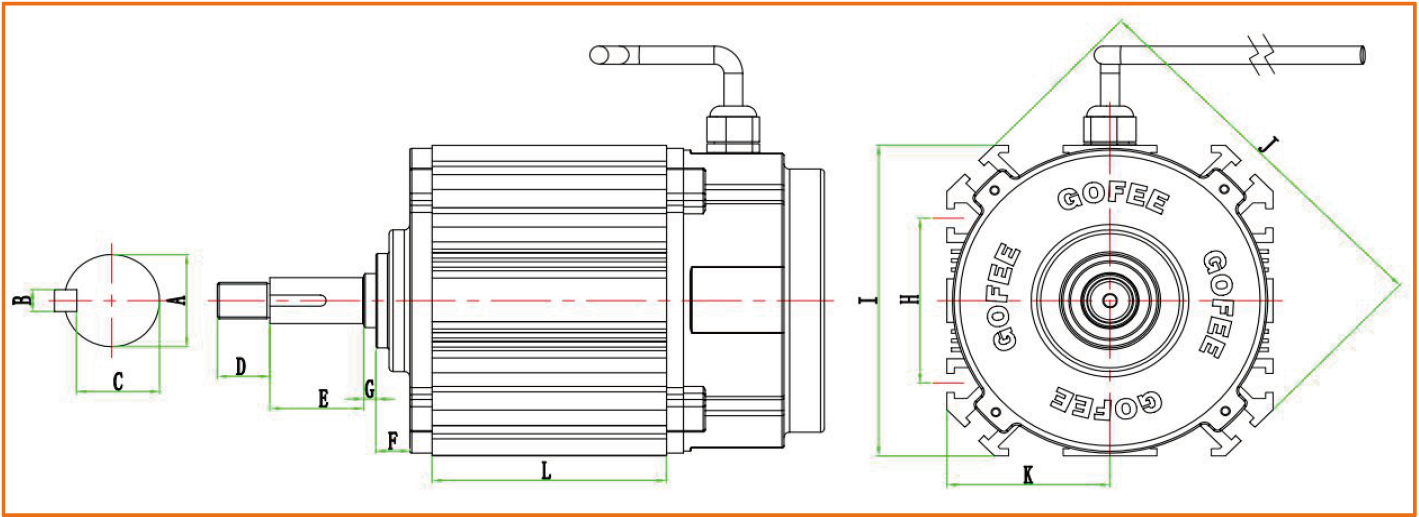

Outline Dimension:(mm)

| Model | CE Certified Model | Outline Dimension | |||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| GFPM 0.37KW-700RPM | GFPM 370-720-380T | Φ24 -0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.55KW-800RPM | GFPM 550-800-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.75KW-1000RPM | GFPM 750-1000-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.75KW-1000RPM | GFPM 750-1000-220 | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.9KW-1000RPM | GFPM 900-1000-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 1.1KW-650RPM | GFPM 1100-650-380T | Φ25.4 -0.01-0.03 | 10 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.1KW-650RPM | GFPM 1100-600-220 | Φ25.4 -0.01-0.03 | 10 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.8KW-750RPM | GFPM 1800-750-220 | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.8KW-750RPM | GFPM 1800-750-380T | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 2.2KW-750RPM | GFPM 2200-750-380T | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 53 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.5KW-650RPM | GFPM 1500-650-220 | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 53 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

Hubei Gongfu Intelligent Equipment Co., Ltd.

Empowering Industry, Forging the Future

We extend a warm invitation to clients and partners worldwide to connect with us. At Gongfu Intelligent, we blend cutting-edge technology with unwavering reliability to deliver customized solutions that drive your success. Our expert team is dedicated to understanding your needs and providing innovative, efficient, and sustainable equipment tailored to your operations.

Whether you are seeking collaboration, technical support, or customized industrial solutions, we are here to assist. Reach out to us today to discover how our expertise can elevate your business.

Contact Us Now – Let’s build a brighter future together!

| Email: | fanmotors@yeah.net |

![High Efficiency Bulk Transportation Feed Truck for Animal Feed Delivery {$v[title]}](https://m.gongfuie.com/uploads/202509/09/fc4bc8ec7c15fe60.jpg)

![Dongfeng 30CBM Bulk Feed Truck {$v[title]}](https://m.gongfuie.com/uploads/202509/08/f1b1f9b8cd19b781.jpg)

![18Ton Dongfeng Livestock Transport Vehicle {$v[title]}](https://m.gongfuie.com/uploads/202509/10/c70b8a0dd41abebd.jpg)

![Dongfeng 20CBM Bulk Feed Truck {$v[title]}](https://m.gongfuie.com/uploads/202509/05/cf091b3c81867b05.png)