Permanent Magnet Synchronous Motor (PMSM / ECM) for Agricultural & Industrial Ventilation

Product Details

Permanent Magnet Synchronous Motor (PMSM / ECM) for Agricultural & Industrial Ventilation

——Upgrade Your Ventilation, Reduce Your Costs with Intelligent ECM Motors

Key Value Proposition: Our Permanent Magnet EC Motors are engineered for superior energy efficiency and intelligent control in demanding ventilation applications. Designed to replace traditional AC induction motors, they deliver significant cost savings, reliable 24/7 operation, and precise environmental management for modern farms and industrial facilities.

Core Advantages:

High Efficiency & Energy Savings: Achieves IE4/IE5 premium efficiency levels, reducing electricity consumption by 30% to 60% compared to conventional motors

Intelligent Variable Speed Control: Seamlessly adjusts fan speed based on temperature, humidity, or gas level sensors (0-10V, PWM control) for optimal airflow and animal comfort

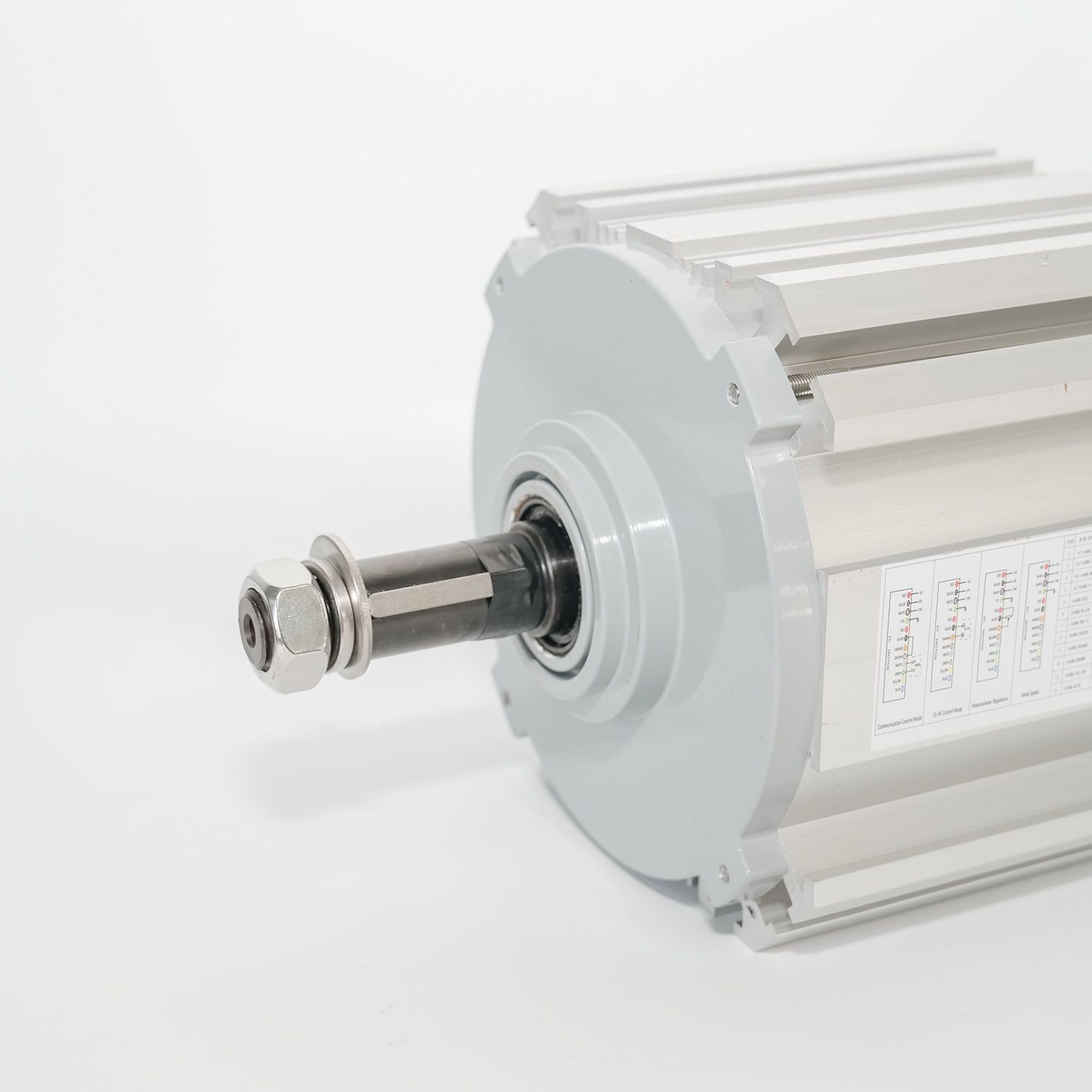

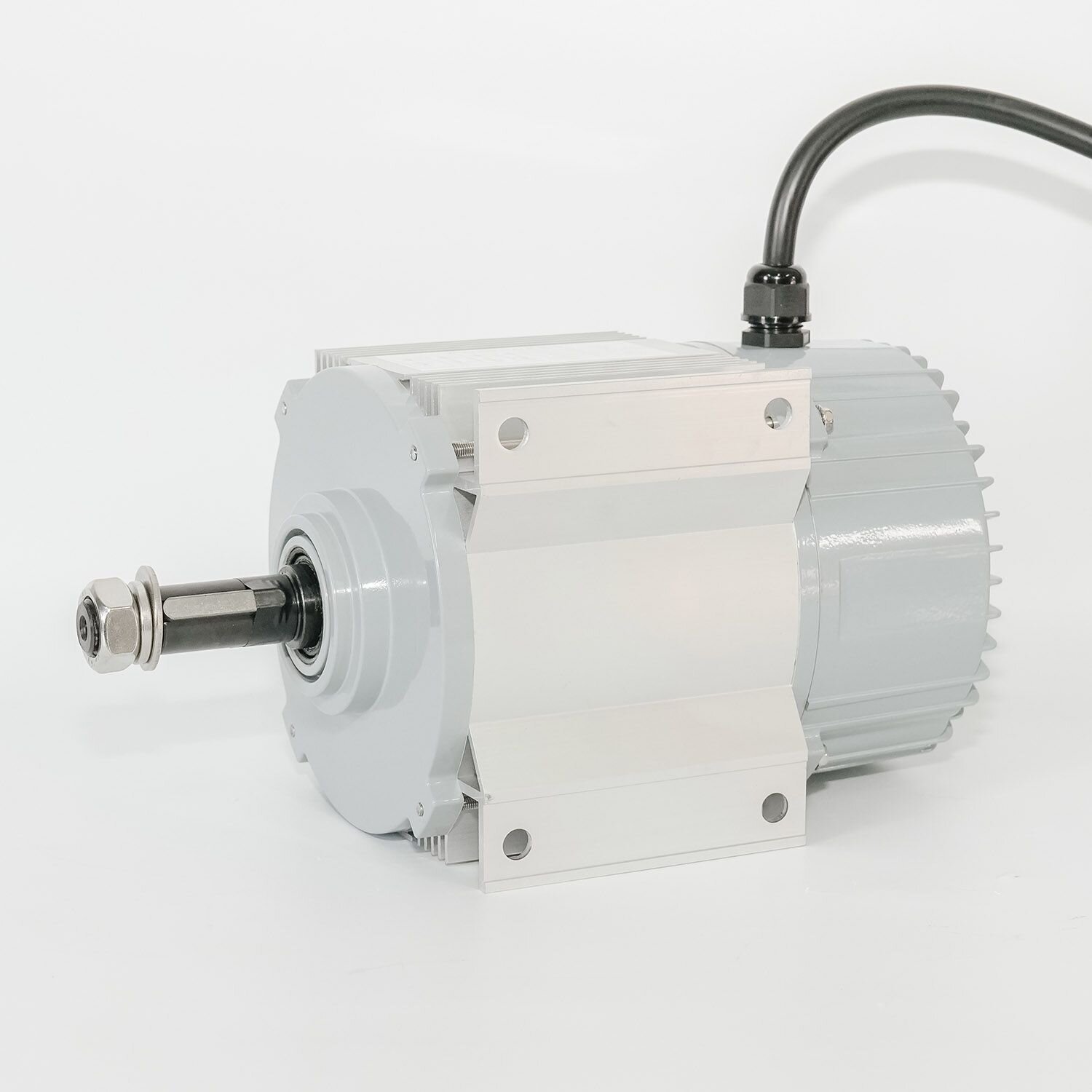

Robust & Maintenance-Free Design: Direct-drive, brushless construction with IP65 protection grade ensures long service life (30,000-60,000 hours) in harsh, corrosive environments.

Stable Operation in Weak Grids: Wide voltage input (e.g., 170V-230V) allows stable operation in rural areas with unstable power supply

.

Main Applications:

Agricultural Ventilation: Livestock barns (poultry, swine, dairy), greenhouse air circulation, agricultural product drying systems.

Industrial Ventilation: Factory workshops, parking garage exhaust, welding fume extraction, HVAC systems.

Why Choose Our ECM Motor over Traditional Motors?

Feature | Our ECM Motor | Traditional Motor | Your Benefit |

|---|---|---|---|

Efficiency | IE5/IE4 (≥90%), energy savings 30%-60% | IE1/IE2, high energy waste | Lower electricity bills, rapid ROI |

Speed Control | Intelligent variable speed (200-1800 RPM) | Fixed speed or limited steps | Precise environment control, improved animal health/air quality |

Durability | Brushless, direct drive, IP65, long lifespan | Belts/gears wear out, less protection | Less downtime, minimal maintenance |

Voltage Adaptability | Wide voltage range (e.g., 170V-230V) | Limited voltage range, unstable in weak grids | Reliable performance in rural/agricultural settings |

Our After-Sales Service & Support:

We are committed to your long-term satisfaction and system uptime.

Global Support Network: We have partnered service centers in key regions to provide prompt technical support and warranty services

OEM/ODM Accepted: We offer customization of motor specifications, mounting, shafts, and control interfaces to meet your specific equipment requirements.

Quality Assurance: Our motors undergo strict testing and carry international certifications like CE to guarantee performance and safety.

Key Features and Benefits

1. Premium Energy Efficiency:

Ultra-High Efficiency: Maintains 90-95% efficiency across entire operating range

Exceptional Energy Savings: Achieves 70-80% reduction in energy consumption

Optimized Operational Economics: Delivers rapid ROI through significant power cost reduction

Environmental Excellence: Supports carbon neutrality goals and sustainable operations

2. Advanced Intelligence and Control:

Adaptive Speed Control: Microprocessor-enabled precise speed matching

Constant Performance Maintenance: Automatic compensation for system variable changes

Soft Start/Stop Technology: <1.2x inrush current compared to running current

Smart System Integration: Seamless BMS compatibility with multiple protocol support

3. Superior Reliability and Performance:

Industrial-Grade Design: Built for 24/7 operation in extreme conditions

Advanced Thermal Management: Intelligent temperature control and protection

Acoustic Optimization: Noise levels below 72 dB(A) at full load

Maintenance-Free Operation: Brushless design with lifetime-lubricated bearings

Technical Specifications

Rated Power: 3000 Watts (4 HP equivalent)

Motor Technology: Advanced brushless DC with high-grade permanent magnets

Control System: Integrated smart variable frequency drive

Input Voltage: 400-480V AC, 50/60Hz (Three Phase)

Control Interfaces:

0-10V DC/4-20mA analog control

PWM signal input

Modbus TCP/BACnet IP protocols

PROFINET/EtherCAT connectivity

IoT-ready for Industry 4.0 applications

Efficiency Class: IE5+ ultra premium efficiency

Protection Rating: IP56/IP65 options available

Thermal Class: H (180°C) insulation system

Service Factor: 1.25 continuous duty

Rated Power: 3000 Watts (4 HP equivalent)

Motor Technology: Advanced brushless DC with high-grade permanent magnets

Control System: Integrated smart variable frequency drive

Input Voltage: 400-480V AC, 50/60Hz (Three Phase)

Control Interfaces:

0-10V DC/4-20mA analog control

PWM signal input

Modbus TCP/BACnet IP protocols

PROFINET/EtherCAT connectivity

IoT-ready for Industry 4.0 applications

Efficiency Class: IE5+ ultra premium efficiency

Protection Rating: IP56/IP65 options available

Thermal Class: H (180°C) insulation system

Service Factor: 1.25 continuous duty

Application Scope

This high-power motor is engineered for extreme-duty industrial applications:

Large Industrial Ventilation Systems

High-Capacity Air Handling Units

Industrial Process Cooling Systems

Data Center Precision Cooling

Large Warehouse Climate Control

Manufacturing Facility Air Management

Emergency Smoke Extraction Systems

Tunnel and Underground Ventilation

Industrial Drying and Process Applications

Large Commercial Complex Pressurization

Performance Advantages:

Energy Efficiency: Up to 80% energy consumption reduction

Control Precision: ±0.5% speed regulation accuracy

Reliability: >120,000 hours design life

Acoustic Performance: <72 dB(A) at 1 meter

Power Factor: >0.99 across operating range

Total Cost of Ownership: 40-50% reduction compared to conventional motors

Smart Features:

Predictive maintenance capability

Remote monitoring and control

Energy consumption tracking

Automated performance optimization

Cloud connectivity for data analytics

Cybersecurity protocols for industrial networks

Summary: The Gongfu ECM motor represents the pinnacle of intelligent motor technology for industrial ventilation applications. It delivers unprecedented energy savings, precise environmental control, and exceptional reliability while dramatically reducing total cost of ownership. Its advanced connectivity features and ultra-premium efficiency make it ideal for modern smart industrial applications and Industry 4.0 implementations, providing both immediate energy savings and long-term operational benefits. The motor's ability to maintain peak efficiency across its entire operating range ensures optimal performance in any operating condition, making it the perfect choice for large-scale ventilation systems where energy efficiency and reliability are paramount.

| Power kw |

Voltage V |

Frequency Hz |

RPM range |

Install Position |

Weight kg |

Efficiency % |

Power factor |

Current | Working Temp |

Torque N.m |

Energy Efficiency |

Protect Grade |

Insulation Class |

Motor Price (USD $) |

Driver Price (USD $) |

| 3 | 220 | 50/60 | 500-3000 | Verical/ Horizontal |

21 | 89.2 | 0.91 | 16.80 | -15~+40℃ | 57.3-9.5 | IE4 | IP66 | F | 341 | 67 |

| 3 | 380 | 50/60 | 500-3000 | Verical/ Horizontal |

21 | 89.2 | 0.91 | 5.62 | -15~+40℃ | 57.3-9.5 | IE4 | IP66 | F | 341 | 67 |

| 3 | 460 | 50/60 | 500-3000 | Verical/ Horizontal |

21 | 89.2 | 0.91 | 4.64 | -15~+40℃ | 57.3-9.5 | IE4 | IP66 | F | 341 | 67 |

| MODEL | Power Voltage | AC motor Labeled power |

AC motor Actual power consume |

EC motor Actual power consume | Power saving per hour (kWh) | Power saving 12 hours per day (kWh) | Monthly power saving (kWh) |

Annual power saving (kWh) | Save USD every year (Note: 0.12$/kWh) |

| GFPM0.37KW-1450RPM | 220V | 370W | 526W | 350W | 176W | 2.11 | 63 | 770.00 | 92.4 |

| GFPM0.55KW-800RPM | 380V | 550W | 800W | 406W | 394W | 4.73 | 142 | 1726.00 | 207.12 |

| GFPM0.55KW-800RPM | 220V | 550W | 900W | 400W | 500W | 6 | 180 | 2190.00 | 262.8 |

| GFPM0.75KW-1000RPM | 380V | 750W | 1130W | 730W | 400W | 4.8 | 144 | 1752.00 | 210.24 |

| GFPM0.75KW-1500RPM | 220V | 750W | 1250W | 850W | 400W | 4.8 | 144 | 1752.00 | 210.24 |

| GPFM1.1KW-650RPM | 380V | 1100W | 1670W | 1160W | 510W | 6.12 | 184 | 2234.00 | 268.08 |

| GFPM-1.1KW-650RPM | 220V | 1100W | 2200W | 1200W | 1000W | 12 | 360 | 4380.00 | 525.6 |

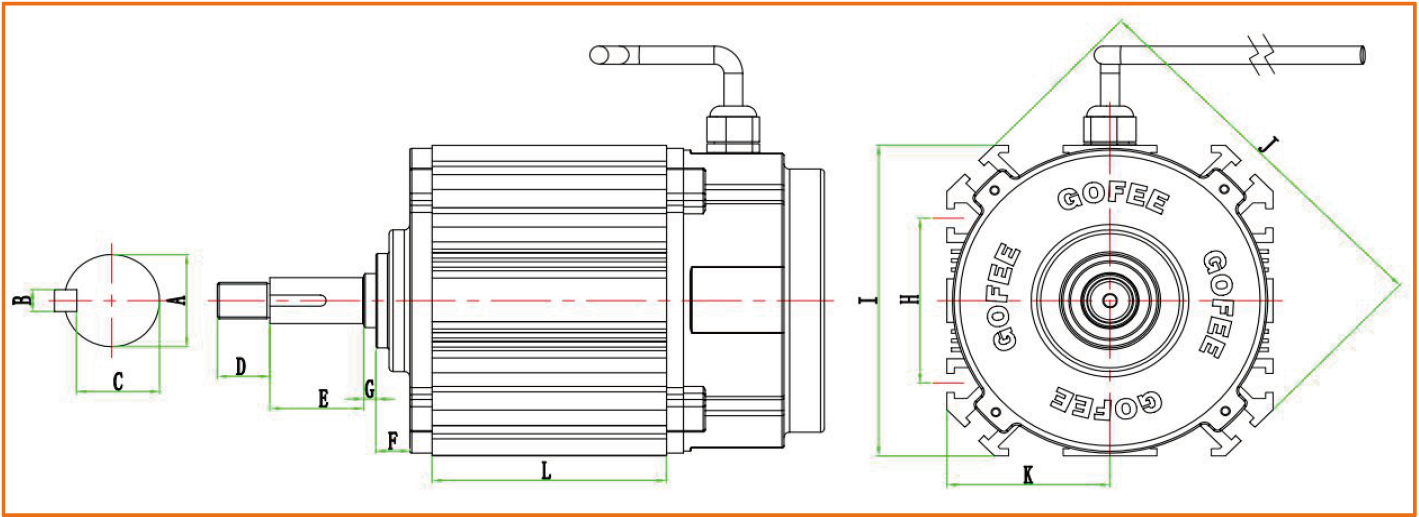

Outline Dimension:(mm)

| Model | CE Certified Model | Outline Dimension | |||||||||||

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| GFPM 0.37KW-700RPM | GFPM 370-720-380T | Φ24 -0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.55KW-800RPM | GFPM 550-800-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.75KW-1000RPM | GFPM 750-1000-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.75KW-1000RPM | GFPM 750-1000-220 | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 0.9KW-1000RPM | GFPM 900-1000-380T | Φ24 0-0.05 | 8 0-0.03 | 20.4 0-0.1 | M20X25 | 50 | 18 | 10 | 77.2 | 151.3 | 179.3 | 78.6 | 122 |

| GFPM 1.1KW-650RPM | GFPM 1100-650-380T | Φ25.4 -0.01-0.03 | 10 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.1KW-650RPM | GFPM 1100-600-220 | Φ25.4 -0.01-0.03 | 10 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.8KW-750RPM | GFPM 1800-750-220 | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.8KW-750RPM | GFPM 1800-750-380T | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 50 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 2.2KW-750RPM | GFPM 2200-750-380T | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 53 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

| GFPM 1.5KW-650RPM | GFPM 1500-650-220 | Φ25.4 -0.01-0.03 | 13 0-0.03 | 21.4 0-0.1 | M20X25 | 53 | 18 | 14.7 | 90.8 | 171.2 | 208 | 86.9 | 125 |

Hubei Gongfu Intelligent Equipment Co., Ltd.

Empowering Industry, Forging the Future

We extend a warm invitation to clients and partners worldwide to connect with us. At Gongfu Intelligent, we blend cutting-edge technology with unwavering reliability to deliver customized solutions that drive your success. Our expert team is dedicated to understanding your needs and providing innovative, efficient, and sustainable equipment tailored to your operations.

Whether you are seeking collaboration, technical support, or customized industrial solutions, we are here to assist. Reach out to us today to discover how our expertise can elevate your business.

Contact Us Now – Let’s build a brighter future together!

| Email: | fanmotors@yeah.net |

![High Efficiency Bulk Transportation Feed Truck for Animal Feed Delivery {$v[title]}](https://m.gongfuie.com/uploads/202509/09/fc4bc8ec7c15fe60.jpg)

![Dongfeng 30CBM Bulk Feed Truck {$v[title]}](https://m.gongfuie.com/uploads/202509/08/f1b1f9b8cd19b781.jpg)

![18Ton Dongfeng Livestock Transport Vehicle {$v[title]}](https://m.gongfuie.com/uploads/202509/10/c70b8a0dd41abebd.jpg)

![Dongfeng 20CBM Bulk Feed Truck {$v[title]}](https://m.gongfuie.com/uploads/202509/05/cf091b3c81867b05.png)